In recent years, the construction industry has experienced a notable shift towards offsite construction methods, which are also known as modular or prefabricated construction.

As a leading expert in modular construction, we embrace offsite construction in our factories in Germany, Poland and Dubai to minimize on-site construction worldwide. Let’s delve into the key advantages of our offsite construction methods.

Offsite construction is an innovative approach that involves assembling building components in a controlled factory environment before transporting them to the construction site for final installation. This method has gained traction across various sectors, revolutionizing the way we build.

Offsite construction provides remarkable time and cost savings compared to traditional on-site construction methods. We leverage production techniques that allow for simultaneous manufacturing and site preparation.

The controlled factory environment reduces the impact of weather conditions and other external factors, ensuring uninterrupted progress. This significantly reduces project timelines, enabling faster completion. Moreover, the reduced construction time translates into lower labor costs, making it a cost-effective choice.

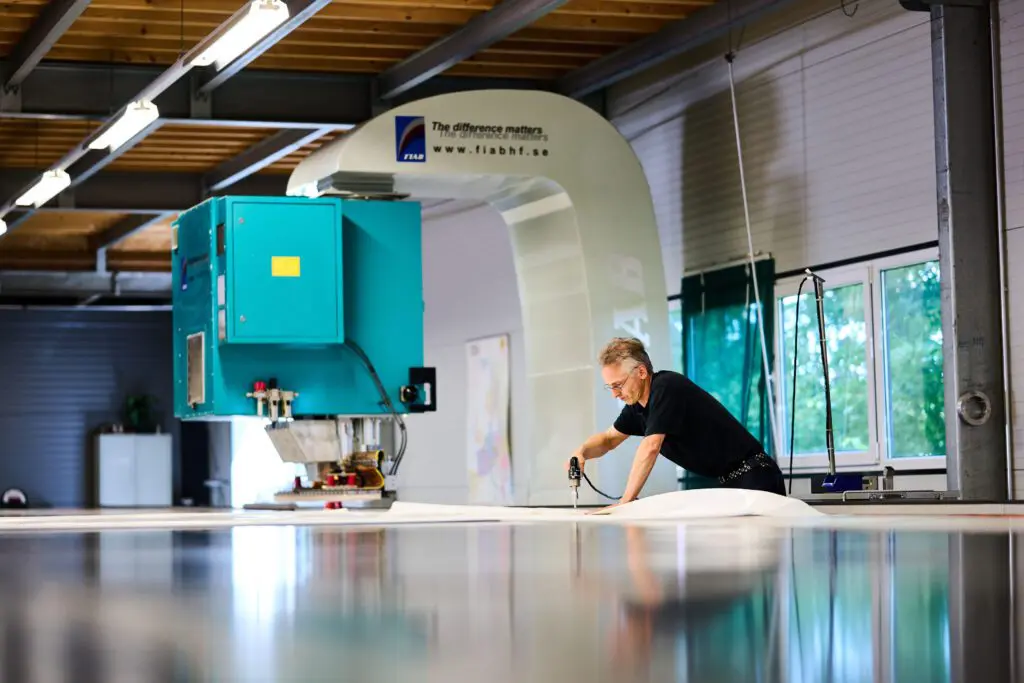

Spantech’s offsite construction process incorporates demanding quality control measures. Building components are manufactured with precision, adhering to strict specifications and guidelines. Our skilled team, supported by advanced machinery and technology, maintains high-quality standards throughout the production process.

We are committed to building for a greener future and prioritize sustainability in our offsite construction practices. The controlled factory environment enables efficient resource utilization and waste reduction.

Spantech’s modular structures can be relocated and repurposed, extending their lifespan. Additionally, the modular nature of our structures allows for future modifications and expansions, providing adaptability to changing needs without constructing an entirely new building.

The benefits of offsite construction are revolutionizing the construction industry. With increased efficiency, enhanced quality, and a steadfast commitment to sustainability, this innovative approach represents the future of construction, or as we like to call it, Construction 2.0.

As the demand for faster, cost-effective, and sustainable building solutions continues to grow, offsite construction emerges as a viable option. Discover the modular solutions offered by Spantech and embark on a construction journey that optimizes efficiency, quality, and sustainability. Contact our team today.

In our pursuit of a more sustainable future, Spantech is always on the lookout for ways to reduce our carbon footprint. One of the strategies we employ is the use of recycled aluminium in our modular structures.

Aluminium, known for its versatility and durability, is an excellent material choice for construction projects. However, what sets recycled aluminium apart is its ability to contribute to a circular economy, reducing waste and conserving valuable resources.

Recycled aluminium refers to the process of reusing aluminium products or scraps to create new materials. What makes aluminium unique is its property of being 100% recyclable, without any loss in quality or performance.

Unlike many other materials, aluminium can be recycled an unlimited number of times, preserving its chemical and mechanical characteristics. This exceptional property of aluminium, its ability to be recycled indefinitely without any loss in quality, paves the way for a sustainable lifecycle approach.

Our modular structures, ranging from industrial buildings to soundstages and event locations, benefit from the numerous advantages offered by recycled aluminium:

By incorporating recycled aluminium in our modular construction projects, we contribute to environmental sustainability. By using recycled materials, demand for primary aluminium extraction is reduced. This, in turn, conserves natural resources and mitigates the environmental impact associated with mining and processing.

For instance, a life cycle analysis conducted by Spantech on our modular soundstage for Wycombe, has provided empirical evidence of its sustainability benefits. By utilizing 40% recycled aluminum in its construction, the modular soundstage demonstrated an impressive 44% reduction in carbon emissions per square meter when compared to a traditional tilt-up concrete stage. This finding serves as a testament to the effectiveness of incorporating sustainable materials like recycled aluminum in construction projects.

Recycled aluminium offers notable energy efficiency advantages compared to primary aluminium production. Producing recycled aluminium requires only 5% of the energy needed for primary aluminium extraction. This translates into lower greenhouse gas emissions and a reduced carbon footprint.

Recycling aluminium, including its application in modular construction, helps to address the issue of waste generation. The material is given a new life. This approach promotes a circular economy, where materials are continually repurposed and reused instead of being disposed of as waste.

The incorporation of recycled aluminium in our modular construction projects represents a significant step towards building in a more environmentally friendly manner. By leveraging the environmental sustainability, energy efficiency, and waste reduction benefits of recycled aluminium, we minimize our carbon footprint and promote a circular economy.

Together, we can create a more environmentally responsible and resource-efficient future. Get in touch with our team today to discover the possibilities.