In today’s world, where environmental consciousness and sustainable practices are at the forefront, industries are embracing innovative approaches to minimize their ecological impact. The construction sector, known for its significant environmental footprint, is undergoing a transformative shift towards sustainability. Comprehensive assessments, such as Life Cycle Assessments (LCAs), play a vital role in measuring and validating green initiatives.

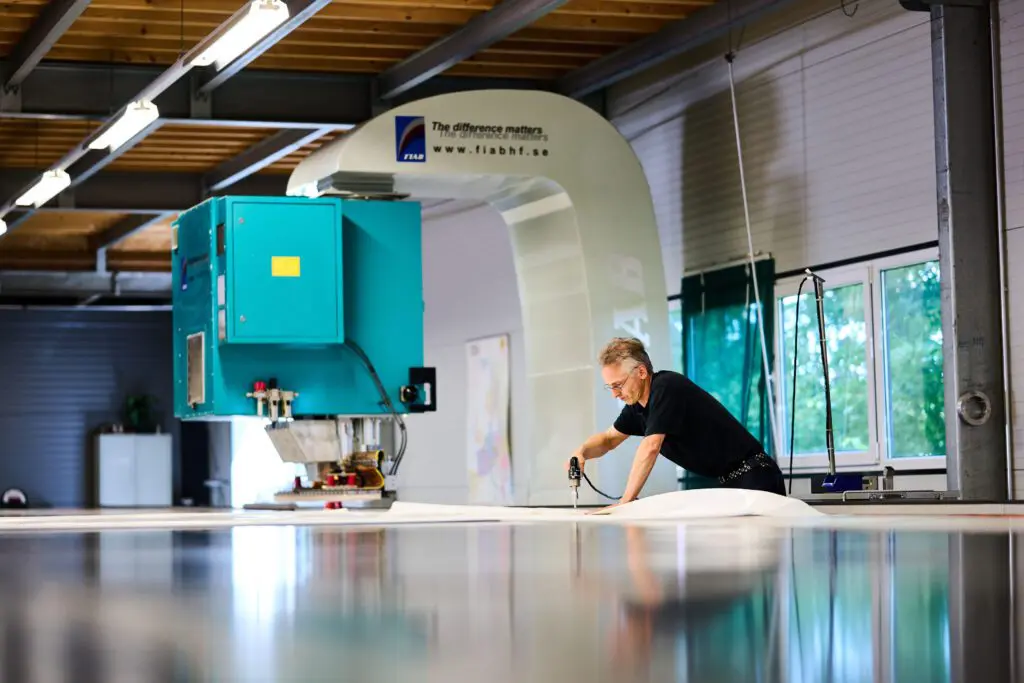

Our innovative Soundstages 2.0 exemplify the company’s dedication to sustainable development. By conducting a rigorous LCA study on the materials used for our soundstages’ construction, Spantech aims to assess the environmental impact, identify areas for improvement, and strengthen their commitment to sustainable practices.

Life Cycle Assessment (LCA) is a method used to measure the environmental impact of a construction product or system throughout its entire lifespan. At Spantech, we embrace LCA as a tool to support our commitment to sustainable construction practices.

LCA considers various stages, including sourcing, production, construction, use, and disposal, to calculate the embodied carbon associated with the materials. By conducting LCA studies, we gain valuable insights into the environmental implications of our choices, enabling us to make informed decisions to minimize our ecological footprint.

In line with our commitment to sustainability, we conducted an LCA study for the materials used for the construction of a Soundstage 2.0.

A good example of a Soundstage 2.0 is the one we constructed for Stage50 in Wycombe. This soundstage was designed for permanent use, features impressive dimensions, measuring 40×50 meters with a generous free height of 12.7 meters. At its apex, the stage reaches a height of 18.5 meters. In addition to the essential elements such as an elephant door, catwalks strategically positioned along the length and width, and a series of REDs spaced every 2.5 meters for enhanced functionality, the soundstage also features a 54db sound insulation.

By highlighting our Soundstages’ eco-friendly features, responsible material choices, and forward-thinking design principles, we aim to inspire others in the industry to embrace sustainable construction practices and contribute to a greener future.

To assess the environmental impact of the Soundstage 2.0 construction over its 45-year lifespan, Spantech conducted a comprehensive Life Cycle Assessment (LCA) study. This study considered all the features described above and employed a rigorous methodology to ensure accurate and reliable results, reflecting Spantech’s commitment to transparency and sustainability.

The LCA study compared the environmental implications of the materials used in a traditional tilt-up concrete stage with those used in the Spantech soundstage, which shared identical characteristics. The goal was to evaluate the environmental benefits of different construction materials. The Spantech soundstage incorporated sustainable materials such as aluminum (including 40% recycled aluminum), steel, and PVC, while the concrete stage represented a conventional construction option.

The study encompassed various stages of the soundstages’ life cycle, including raw material extraction, production, construction, use, demolition, recycling, and waste disposal. By focusing on the embodied carbon associated with the building elements, the study provided valuable insights into the environmental impact of the construction process.

The LCA study provided valuable insights into the environmental impact of the materials used in the construction of a Soundstage 2.0 compared to the construction of a traditional tilt-up concrete stage.

The Spantech soundstage utilized materials such as recycled aluminum, steel, and PVC, which contribute to its eco-friendly profile. The inventory analysis results demonstrated the positive environmental implications of these material choices.

In terms of embodied carbon emissions, the Spantech soundstage constructed with 40% recycled aluminum showed an impressive reduction of 44% per square meter compared to the tilt-up concrete stage. This significant decrease in carbon emissions highlights the effectiveness of using sustainable materials like recycled aluminum in reducing the environmental impact of construction projects.

Furthermore, the incorporation of sustainable steel in the Spantech soundstage further enhanced its environmental performance. By carefully sourcing steel materials that adhere to recognized environmental standards, Spantech ensured the structural integrity of the soundstage while minimizing the ecological footprint associated with steel production.

Lastly, The LCA study focused on the use of recycled aluminium and steel, but it also highlights the potential benefits of incorporating structural wood in construction. Cross-laminated timber (CLT) is a sustainable alternative to traditional concrete slabs for heavy-duty flooring in soundstages. CLT is durable, load-bearing, and demountable, allowing for easy disassembly and reuse. This reduces waste and maximizes resource efficiency, without the breakdown costs associated with concrete. By embracing sustainable alternatives like CLT, the construction industry can contribute to a greener future and help create a more sustainable world.

In conclusion, the Soundstage 2.0 LCA study reinforces Spantech’s commitment to sustainability. It showcases significant strides in reducing carbon emissions and promoting resource efficiency. Spantech acknowledges the need for continuous improvement and is dedicated to advancing its sustainability initiatives.

The study highlights the environmental drawbacks of the tilt-up concrete stage compared to Spantech’s approach. Spantech’s use of recycled aluminium, sustainable steel, and eco-friendly design exemplifies a more environmentally friendly approach.

Moving forward, Spantech will take concrete actions to increase recycled aluminium usage, explore structural wood benefits, and focus on our eco design principles. By setting an example and pursuing continual progress, Spantech is optimistic about fostering sustainable construction practices and taking part in the future of construction 2.0.

Together with industry partners, Spantech believes in driving positive change and achieving remarkable environmental stewardship advancements.

As Spantech celebrates its 25th anniversary, we stand at a crossroads of history and innovation, where the enduring legacies of architectural pioneers blend seamlessly with our vision for the future of construction. This milestone invites us to delve deeper into the pioneering techniques of Gustave Eiffel, Jean Prouvé, and Mies van der Rohe, whose groundbreaking […]

In the fast-paced world of event marketing, the ability to adapt and execute brand activation events quickly and efficiently is not just an advantage—it’s essential. Traditional event setups often fall short in meeting the urgent demands of the industry, plagued by logistical challenges that can derail even the most meticulously planned events. The Challenges of […]

“The next normal in construction.” That’s how McKinsey & Company referred to modular construction in their groundbreaking 2020 report. Not only does modular construction offer the potential for projects to be completed 50% faster and 20% cheaper than traditional methods, but industry experts predict that by 2030, it could capture $130 billion of the market, […]