“The next normal in construction.” That’s how McKinsey & Company referred to modular construction in their groundbreaking 2020 report. Not only does modular construction offer the potential for projects to be completed 50% faster and 20% cheaper than traditional methods, but industry experts predict that by 2030, it could capture $130 billion of the market, delivering annual savings of $22 billion in the US and Europe alone.

Modular construction, or construction 2.0 as we like to call it, is here to stay. At Spantech, we take pride in being at the forefront of this exciting shift. With over 20 years of experience in the sector, we possess the knowledge and expertise that make modular construction a permanent fixture in the construction landscape.

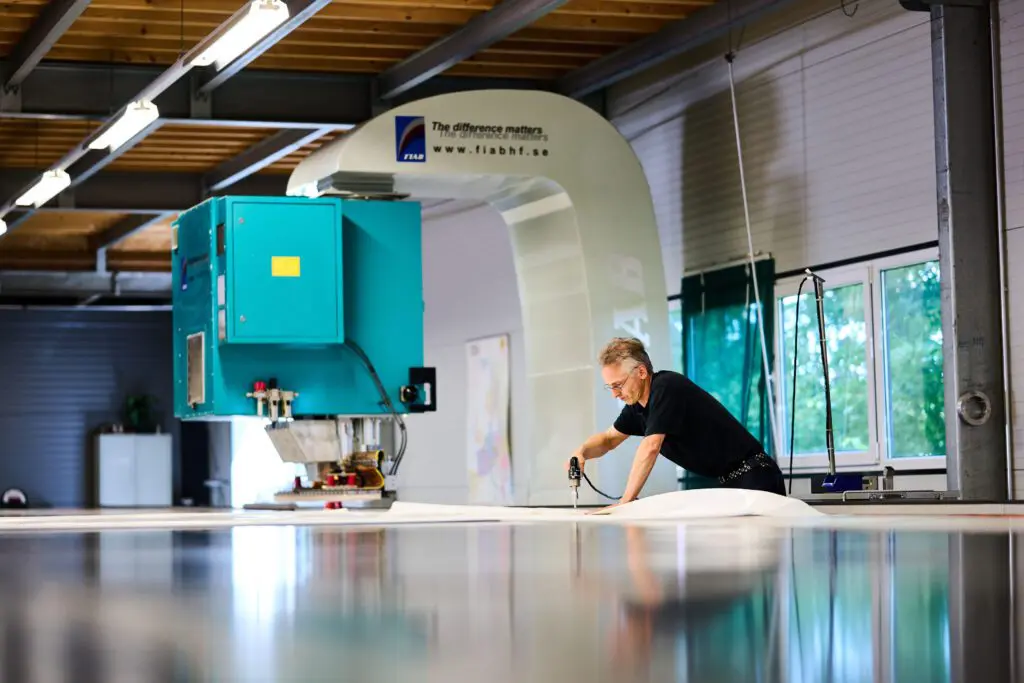

Modular construction, also known as off-site construction, involves the manufacturing of building components in controlled factory settings. These components, or modules, are then transported to the construction site for assembly. This has multiple advantages:

1. Speed and Efficiency: With the ability to fabricate modules simultaneously with site preparation, construction timelines can be significantly reduced. Projects can be completed up to 50% faster than traditional construction methods.

2. Quality Control: In our factories, modules are produced with precision and rigorous quality standards. By minimizing the impact of external factors like weather conditions, we achieve consistently high-quality construction.

3. Sustainability and Waste Reduction: Modular construction offers an eco-friendly alternative to traditional building methods. The controlled production environment allows for efficient material usage and waste reduction.

At Spantech, sustainability is our priority. We utilize recycled aluminum in the construction of our structures, resulting in a substantial reduction in overall carbon emissions. For instance, our modular soundstage for Wycombe Studios achieved a remarkable 44% decrease in carbon emissions per square meter by incorporating 40% recycled aluminum, compared to a traditional tilt-up concrete soundstage. Explore more about our use of recycled aluminum in our structures.

4. Cost Savings: Modular construction provides significant cost savings throughout the project lifecycle. The streamlined production process, reduced labor costs, and improved resource management all contribute to overall project cost reduction.

5. Enhanced Design Freedom: With modular construction, you gain design freedom and flexibility. Our advancements in manufacturing techniques and customization capabilities empower us to bring unique architectural designs to life. From industrial modular buildings to stunning event structures like our orangery, Grand I-novation or soundstage, Spantech’s modular construction solutions cater to a diverse range of architectural visions.

As Spantech celebrates its 25th anniversary, we stand at a crossroads of history and innovation, where the enduring legacies of architectural pioneers blend seamlessly with our vision for the future of construction. This milestone invites us to delve deeper into the pioneering techniques of Gustave Eiffel, Jean Prouvé, and Mies van der Rohe, whose groundbreaking […]

In the fast-paced world of event marketing, the ability to adapt and execute brand activation events quickly and efficiently is not just an advantage—it’s essential. Traditional event setups often fall short in meeting the urgent demands of the industry, plagued by logistical challenges that can derail even the most meticulously planned events. The Challenges of […]

In today’s world, where environmental consciousness and sustainable practices are at the forefront, industries are embracing innovative approaches to minimize their ecological impact. The construction sector, known for its significant environmental footprint, is undergoing a transformative shift towards sustainability. Comprehensive assessments, such as Life Cycle Assessments (LCAs), play a vital role in measuring and validating […]